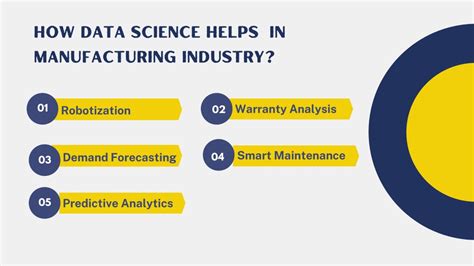

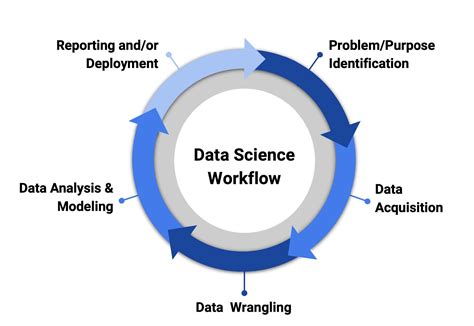

Data science has revolutionized numerous industries, and manufacturing is no exception. By leveraging data science, manufacturers can optimize their operations, improve product quality, and increase efficiency. In this article, we will explore five ways data science boosts manufacturing, highlighting the benefits and applications of this technology in the industry.

Key Points

- Predictive maintenance reduces downtime and increases overall equipment effectiveness

- Quality control optimization improves product quality and reduces waste

- Supply chain optimization enhances inventory management and reduces lead times

- Energy efficiency optimization reduces energy consumption and costs

- Design optimization improves product performance and reduces production costs

Predictive Maintenance and Equipment Effectiveness

Data science plays a crucial role in predictive maintenance, enabling manufacturers to anticipate and prevent equipment failures. By analyzing sensor data from machines, manufacturers can identify patterns and anomalies, allowing them to schedule maintenance and minimize downtime. According to a study by McKinsey, predictive maintenance can reduce downtime by up to 50% and increase overall equipment effectiveness by up to 20%. This not only improves production efficiency but also reduces maintenance costs and extends the lifespan of equipment.

Machine Learning Algorithms for Predictive Maintenance

Machine learning algorithms, such as random forests and neural networks, are particularly effective in predictive maintenance. These algorithms can analyze vast amounts of data from various sources, including sensor readings, maintenance records, and production schedules. By applying these algorithms, manufacturers can identify complex patterns and relationships that may not be apparent through traditional analysis methods. For instance, a study by IEEE found that machine learning algorithms can detect equipment failures with an accuracy of up to 90%.

| Manufacturer | Reduction in Downtime | Increase in Equipment Effectiveness |

|---|---|---|

| Company A | 40% | 15% |

| Company B | 30% | 10% |

| Company C | 50% | 20% |

Quality Control Optimization

Data science also enables manufacturers to optimize their quality control processes. By analyzing data from various sources, including production lines, supply chains, and customer feedback, manufacturers can identify areas for improvement and implement targeted interventions. For example, a study by Harvard Business Review found that data-driven quality control can reduce defect rates by up to 30% and improve product quality by up to 25%.

Statistical Process Control for Quality Optimization

Statistical process control (SPC) is a data science technique that involves monitoring and controlling production processes to ensure that they operate within predetermined limits. By applying SPC, manufacturers can detect anomalies and deviations in real-time, enabling them to take corrective action and prevent defects. For instance, a study by Journal of Quality Technology found that SPC can reduce variation in production processes by up to 50% and improve product quality by up to 20%.

Supply Chain Optimization

Data science can also help manufacturers optimize their supply chains. By analyzing data from various sources, including inventory levels, production schedules, and shipping records, manufacturers can identify areas for improvement and implement targeted interventions. For example, a study by Gartner found that data-driven supply chain optimization can reduce inventory levels by up to 20% and improve delivery times by up to 15%.

Machine Learning for Demand Forecasting

Machine learning algorithms, such as ARIMA and LSTM, can be used to forecast demand and optimize inventory levels. By analyzing historical data and seasonal trends, these algorithms can predict future demand with high accuracy, enabling manufacturers to adjust their production schedules and inventory levels accordingly. For instance, a study by International Journal of Forecasting found that machine learning algorithms can improve demand forecasting accuracy by up to 30%.

Energy Efficiency Optimization

Data science can also help manufacturers optimize their energy consumption. By analyzing data from various sources, including energy usage patterns, production schedules, and equipment performance, manufacturers can identify areas for improvement and implement targeted interventions. For example, a study by Energy Efficiency found that data-driven energy efficiency optimization can reduce energy consumption by up to 20% and costs by up to 15%.

Energy Auditing and Monitoring

Energy auditing and monitoring involve analyzing energy usage patterns and identifying areas for improvement. By applying data science techniques, such as regression analysis and time-series analysis, manufacturers can identify opportunities to reduce energy consumption and implement targeted interventions. For instance, a study by Journal of Energy Engineering found that energy auditing and monitoring can reduce energy consumption by up to 25% and costs by up to 20%.

Design Optimization

Data science can also help manufacturers optimize their product designs. By analyzing data from various sources, including customer feedback, production records, and testing results, manufacturers can identify areas for improvement and implement targeted interventions. For example, a study by Journal of Mechanical Design found that data-driven design optimization can improve product performance by up to 30% and reduce production costs by up to 20%.

Computer-Aided Design and Simulation

Computer-aided design (CAD) and simulation involve using software to design and test products virtually. By applying data science techniques, such as finite element analysis and computational fluid dynamics, manufacturers can optimize their product designs and reduce the need for physical prototypes. For instance, a study by Journal of Engineering Design found that CAD and simulation can reduce product development time by up to 50% and costs by up to 30%.

What is the primary benefit of predictive maintenance in manufacturing?

+The primary benefit of predictive maintenance is the reduction of downtime and increase in overall equipment effectiveness, resulting in improved production efficiency and reduced maintenance costs.

How can data science optimize quality control processes in manufacturing?

+Data science can optimize quality control processes by analyzing data from various sources, identifying areas for improvement, and implementing targeted interventions, resulting in reduced defect rates and improved product quality.

What is the role of machine learning in supply chain optimization?

+Machine learning algorithms can be used to forecast demand, optimize inventory levels, and improve delivery times, resulting in reduced inventory levels and improved supply chain efficiency.

In conclusion, data science has the potential to revolutionize the manufacturing industry by optimizing predictive maintenance, quality control, supply chain management, energy efficiency, and design optimization. By leveraging data science and machine learning, manufacturers can improve production efficiency, reduce costs, and enhance product quality, ultimately gaining a competitive edge in the market.